Description

Quick Details

- Condition: New Brand Name: Shearchy Machine Type: 3 Roller Plate Bending Rolls

- Raw Material:Steel plate Power: Hydraulic Certification: ISO, SGS, CE

- After-sales Service Provided: Engineers available to service machinery oversea Warranty: 13 months

Product Description

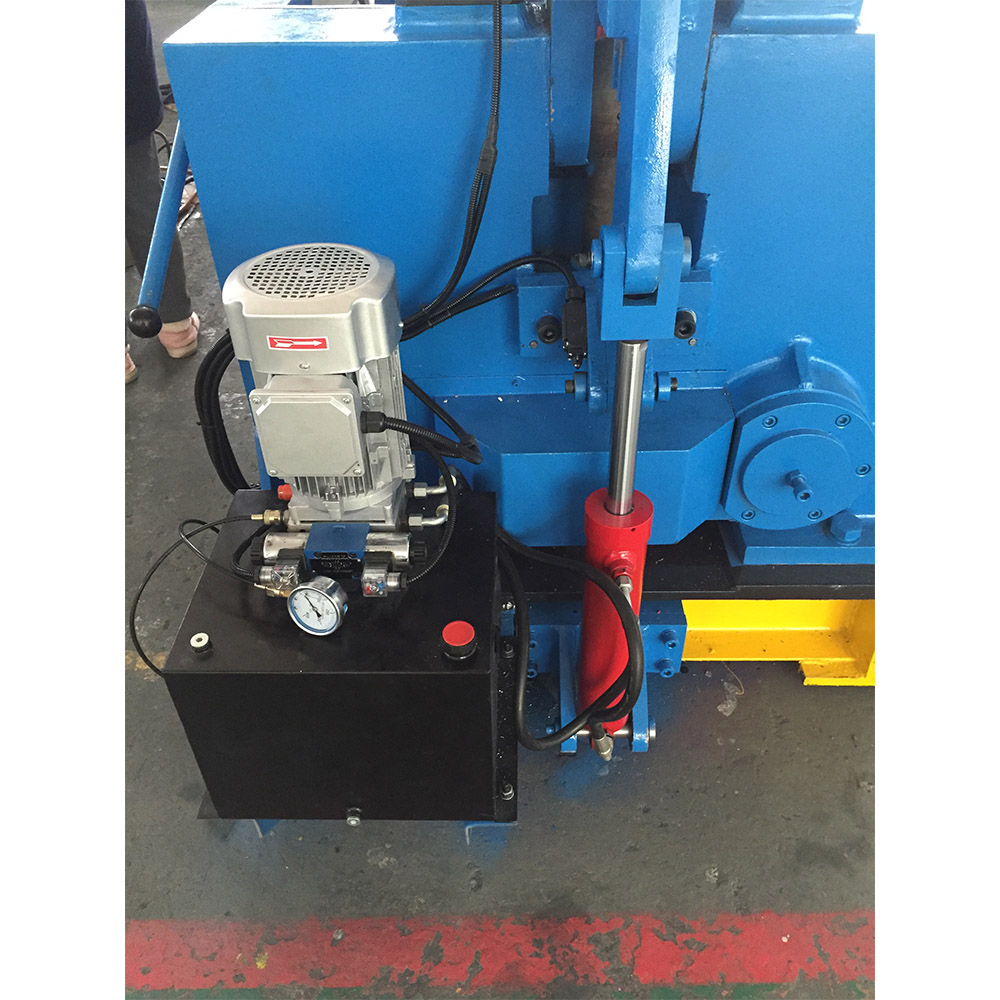

The upper roller of 3 Roller Plate Rolls makes vertical lifting movement at symmetry place of two bottom rollers center, through hydraulic oil in the hydraulic cylinder acting on piston pole, so it is hydraulic transmission.

Two bottom rollers make rotary movement. Motor joins bottom roller through gear reducer and universal chain coupler, providing torque for rolling plate.

Under the two bottom rollers, there are multiple sets of support rollers, which can improve the rigidity of the bottom rollers.

Configuration:

- Main low-voltage electric elements:SCHNEIDER/ OMRON

- Programmable controller PLC:Japanese Mitsubish

- Touch screen(LCD):Taiwan HITECH

- Airtight grating:Made in China

- Rollers:Material 42CrMo precision forging

- Tempered on HB270~300

- Cylinder:No.45 Steel tempered, boring inner hole,Rolling press and grinded

- Piston rod:No.45 Steel tempered, plating nickel and phosphor outside.

- Main seal of oil cylinder:Japanese NOK

- Motors:Siemens

- Hydraulic system: Rexroth,Germany.