Description

Quick Details

- Condition: New Brand Name: Shearchy Machine Type: 4 Roller Plate Bending Rolls

- Raw Material:Steel plate Power: Hydraulic Certification: ISO, SGS, CE

- After-sales Service Provided: Engineers available to service machinery oversea Warranty: 13 months

Product Description – 4 Roller Plate Bending Rolls

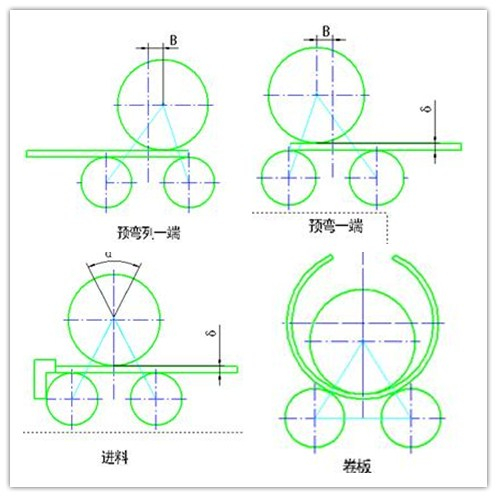

Shearchy 4 roller bend rolling machine is the general equipment used for bending/rolling plates. Pre-bending and bending can be completed on the machine without U-turn. Plates can be bended to be tubular, arc or even cone-shaped work pieces with supplemental device. The machine is optimal equipment with four rollers to bend metal plates.

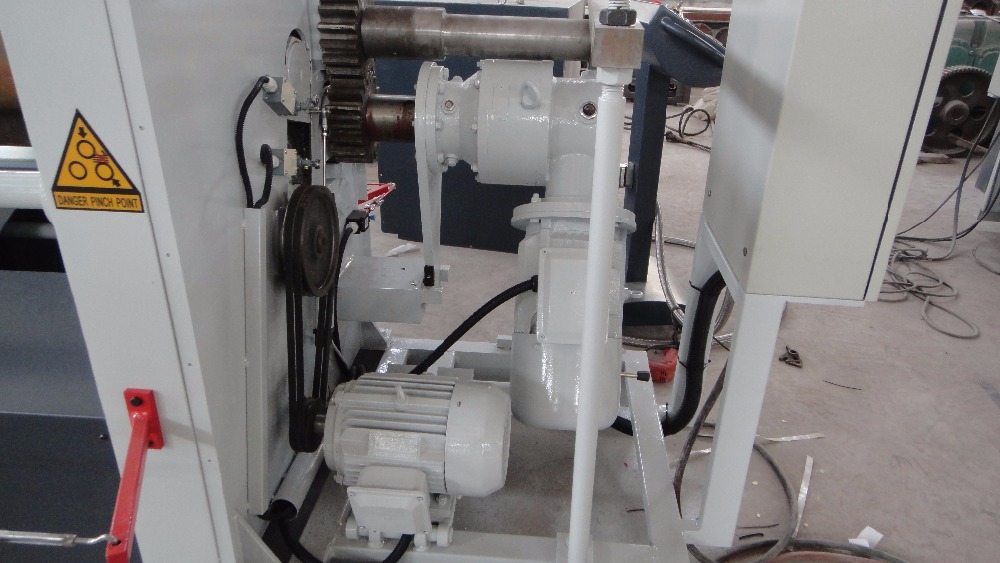

The upper roller is main drive roller, bottom roller and two side rollers make vertical movement to tighten the plate.

Vertical movement close to upper roller adjust circle radius.

Small straight edge of pre-bending.

High rolling precision.

Roll taper workpiece with full generatrix.

Rollers moving position control by computer.

Highest rolling efficiency and capacity.

Configuration- 4 Roller Plate Bending Rolls:

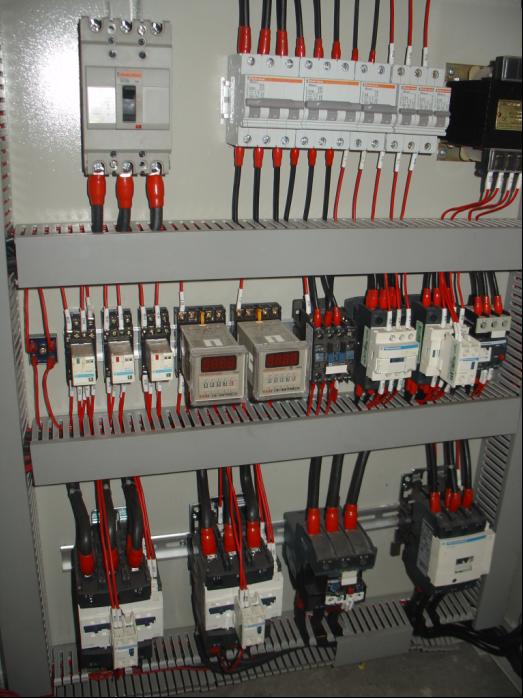

- Main low-voltage electric elements:SCHNEIDER/ OMRON

- Programmable controller PLC:Japanese Mitsubish

- Touch screen(LCD):Taiwan HITECH

- Airtight grating:Made in China

- Rollers:Material 42CrMo precision forging

- Tempered on HB270~300

- Cylinder:No.45 Steel tempered, boring inner hole,Rolling press and grinded

- Piston rod:No.45 Steel tempered, plating nickel and phosphor outside.

- Main seal of oil cylinder:Japanese NOK

- Motors:Siemens

- Hydraulic system: Rexroth,Germany.

Technical Data – 4 Roller Plate Bending Rolls

| Model | Useful length(mm) | Min.diameter=top roller φx5 | Min.diameter=Top roller φx5(1.5-2) | Top roller dia (mm) | Bottom roller dia (mm) | Sideroller dia (mm) | Main Motor (KW) |

Rolling Speed (m/min) | Overall dimension L*W*H (mm) | Wight(ton) | ||

| Without prebend |

With prebend |

Without prebend |

With prebend |

|||||||||

| W12-12×2000 | 2000 | 12 | 9 | 6 | 220 | 220 | 160 | 7.5 | 3-5 | 4500x1500x1400 | 5 | |

| W12-16×2000 | 2000 | 16 | 12 | 8 | 260 | 240 | 200 | 11 | 3-5 | 4100x1700x1800 | 6.7 | |

| W12-20×2000 | 2000 | 20 | 16 | 12 | 280 | 260 | 220 | 18.5 | 3-5 | 4600x1950x1900 | 9.6 | |

| W12-25×2000 | 2000 | 25 | 20 | 16 | 310 | 290 | 250 | 22 | 3-5 | 4800x2000x2000 | 11.3 | |

| W12-30×2000 | 2000 | 30 | 25 | 20 | 360 | 330 | 270 | 30 | 3-5 | 5100x2100x2000 | 13 | |

| W12-8×2500 | 2500 | 8 | 6 | 4 | 220 | 200 | 160 | 7.5 | 3-5 | 5000x1500x1400 | 6 | |

| W12-12×2500 | 2500 | 12 | 9 | 6 | 250 | 230 | 180 | 11 | 3-5 | 5100x1500x1400 | 7.1 | |

| W12-16×2500 | 2500 | 16 | 12 | 8 | 280 | 260 | 220 | 15 | 3-5 | 5100x1950x1900 | 10.2 | |

| W12-20×2500 | 2500 | 20 | 16 | 12 | 330 | 310 | 250 | 22 | 3-5 | 5300x2000x2000 | 12 | |

| W12-25×2500 | 2500 | 25 | 20 | 16 | 360 | 330 | 270 | 30 | 3-5 | 5600x2100x2000 | 15 | |

| W12-30×2500 | 2500 | 30 | 25 | 20 | 390 | 360 | 290 | 37 | 3-5 | 5600x2250x2100 | 18 | |

| W12-40×2500 | 2500 | 40 | 35 | 30 | 470 | 440 | 380 | 45 | 3-5 | 6100x2550x2700 | 25.5 | |

| W12-50×2500 | 2500 | 50 | 40 | 35 | 510 | 480 | 410 | 55 | 3-5 | 6100x3100x2700 | 36 | |

| W12-60×2500 | 2500 | 60 | 50 | 40 | 560 | 530 | 450 | 75 | 3-5 | 6500x3200x3000 | 48 | |

| W12-6×3000 | 3000 | 6 | 5 | 4 | 220 | 200 | 160 | 7.5 | 3-5 | 5500x1500x1400 | 7 | |

| W12-8×3000 | 3000 | 8 | 6.5 | 5 | 250 | 230 | 180 | 11 | 3-5 | 5600x1500x1400 | 9 | |

| W12-12×3000 | 3000 | 12 | 9 | 6 | 280 | 260 | 220 | 15 | 3-5 | 5700x1950x1900 | 12 | |

| W12-16×3000 | 3000 | 16 | 12 | 8 | 330 | 310 | 250 | 22 | 3-5 | 2900x2000x2000 | 14 | |

| W12-20×3000 | 3000 | 20 | 16 | 12 | 360 | 330 | 270 | 30 | 3-5 | 6100x2150x2000 | 17 | |

| W12-25×3000 | 3000 | 25 | 20 | 16 | 390 | 360 | 290 | 37 | 3-5 | 6100x2250x2100 | 20 | |

| W12-30×3000 | 3000 | 30 | 25 | 20 | 410 | 380 | 320 | 45 | 3-5 | 6300x2500x2400 | 23 | |

| W12-35×3000 | 3000 | 35 | 30 | 25 | 470 | 440 | 380 | 45 | 3-5 | 6600x2550x2700 | 28 | |

| W12-40×3000 | 3000 | 40 | 35 | 30 | 510 | 480 | 410 | 55 | 3-5 | 6600x2600x2750 | 39 | |

| W12-50×3000 | 3000 | 50 | 40 | 35 | 560 | 530 | 450 | 66 | 3-5 | 6600x3200x3000 | 51 | |

| W12-60×3000 | 3000 | 60 | 50 | 40 | 650 | 620 | 520 | 75 | 3-5 | 7000x3300x3400 | 74 | |

| W12-70×3000 | 3000 | 70 | 60 | 50 | 700 | 670 | 550 | 90 | 3-5 | 7200x3500x3600 | 89 | |