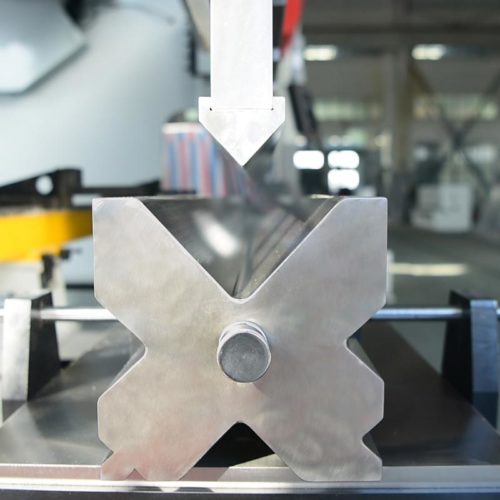

We can devide Press Brake Tools into upper and lower dies, used for sheet metal forming and separation. The forming die has a cavity. And the separating die has a cutting edge.

CNC Hydraulic Press Brake Dies Dent and Corrosion Problems

In the use, the bending die of brake press machine sometimes has dents.

Why does Press Brake Tools have dents?

Then, there are 5 main reasons for this.

Causes of Bending Dent

- The thickness of each part of the bending mold is different.

- The press brake tooling performance is not suitable for work piece forming.

- The design of bending die is unreasonable.

- The quality problems in the production process of punch and die.

- The V-shaped opening of brake press dies is too large.

How to Prevent Bending Tools Corrosion and Dent?

Generally speaking, the quality and performance of press brake tooling is closely related to 5 aspects. In detail, it includes materials, manufacturing, technology, usage and working environment.

-

Material selection of bending machine mould

In general, manufacturers use T7 steel or T8 steel. Better than that is the 42CrMo material. The choice of cold mold steel, which requires high strength, high toughness and good wear resistance. In addition, 42CrMo is alloy quenched and tempered steel with high strength. So, it has high strength and toughness. And, it can work well under 500 ℃. In a word, the selection of die material for CNC hydraulic press brakes is the basis of successful manufacturing.

-

Manufacturing Process

Down → Forging → Tempering → Finishing → Quenching → Annealing → Conditioning → Coarse Grinding → Finishing → Inspection → Packaging → Factory

Press Brake Dies Manufacturing Precautions

-

Development Trend of Technology

From the development process of CNC hydraulic press brake tools:

- From the end of the 19th century to the middle of the 20th century, high speed steel was the main representative of the mold material.

- 1927, Germany first developed the carbide CNC bending machine mold material and obtained wide application.

- In the 1950s, Sweden and the United States respectively synthesized synthetic diamond, cutting CNC bending machine mold has since entered the period represented by super-hard materials.

- In 1970s, polycrystalline diamond (PCD) was synthesized by high pressure synthesis technology. Thus, the problem of rare quantity and high price of natural diamond is solved. The application scope of CNC plate bending machine mold is extended to many fields. Such as aviation, aerospace, automobile, electronics, stone and so on.

Press Brake Punch and Die Techniques Development Direction

-

Press Brake Machine and Tooling Usage

If you want to know something about bending machine and tool usage, please click here: How Adjust Press Brake Tooling Components?

-

Working Environment

Finally, keep the workshop working environment dry and ventilated. No humidity and high temperature! Also, Clean and lubricate the machine regularly. Last but not the least, clean the working environment.