After receiving a new bending machine, users will feel helpless. Before CNC plate bending machines put into use and production, we need to set and adjust the parameters of each press brake tooling.

CNC Press Brake Tooling Parameters Setting and Adjustment

Important brake press machine parameter settings:

Bending force, back gauge distance, the upper limit of slider, slider movement speed, lower die clearance, etc.

According to your actual processing requirements and production operations, how should we verify and adjust the parameters?

-

Bending Pressure or Force

You can calculate according to the calculation formula.

Click here for details: Press Brake Tonnage Calculation

-

Press Brake Backgauge

The back gauge mechanism is used for positioning in the length direction when the sheet metal bent. We can control the motor regulation through the button on the control panel, that is, the electric regulation mode. Than, we can read the adjustment value from the revolution table in the button box. The other is manual fine-tuning mode, that is, fine-tuning by hand wheel device.

-

Slider Limit Adjustment

The adjustment of the upper limit of the slide block of the bending machine needs to be realized by adjusting the position of the bump block.

Make the rising slider stay at the required top dead center position, so as to shorten the stroke distance of the slider, thus reducing the cycle time of work and improving the production efficiency. Touch the travel switch to make the slider move slowly. So, the length of the slow travel time can be adjusted by the potentiometer.

-

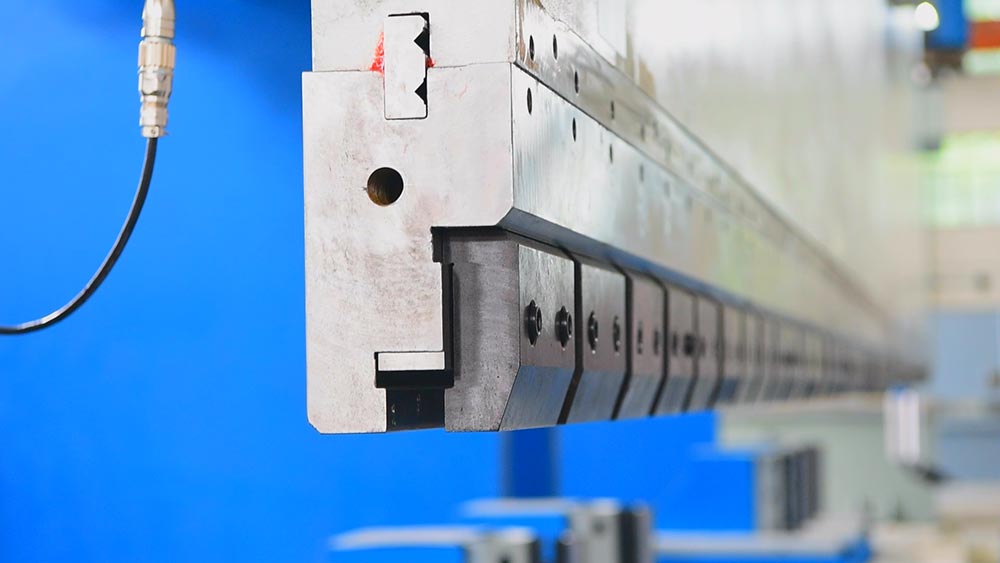

Upper and Lower Die Clearance

Through the buttons on the workbench, we can change the gap between the upper die and lower die of press brake tooling.

More information bout press brake punch and die purchase and usage, you can click here:

CNC Press Brake Dies and Punches Common Sense

We supply a large range of punches, Vee dies, adaptors and clamps to suit most types of Press Brake machines. Also, tooling is available to suit all mounting tangs. Welcome to contact with your demands!