In recent years, the demand for robotic plate bending machine has increased. And the application cases of industrial robots in the country have increased rapidly, mainly in welding, spraying, handling and other fields, and there are not many applications in bending.

The bending of work pieces is a widely used and dangerous job. Therefore, the market prospect of robots is very optimistic, and there are already many successful experiences abroad.

At present, 40%-50% of the bending machines in sheet metal processing workshops in the European and American markets are equipped with robotic automatic bending systems, while China’s current bending automation has just started.

In the next 10 years, domestic demand for bending machine robots will rise sharply.

The CNC sheet metal bending flexible processing unit with the robot as the core execution component is a highly automated equipment combination, which has the advantages of high efficiency, high quality and high flexibility.

In the bending flexible processing unit, choosing the right combination of components can provide better support for improving processing efficiency and flexibility.

The bending accuracy is determined by the speed matching of the robot and the bending machine, and the trajectory of the workpiece entrusted by the robot. The poor follow-up effect will seriously affect the bending angle formation effect and the flatness of the board surface, thereby affecting the quality of the finished product.

1. Advantages of robotic plate bending

- Save manpower

With the development of society, labor costs are getting higher and higher, and workers are difficult to recruit, difficult to manage, and hidden high costs.

The robot can work 24 hours a day, work hard, be on call, safe, and low cost.

- Consistent artifacts

Manual bending will fluctuate with the worker’s experience and the worker’s mood swings.

Robot bending has no mood swings and no experience, which can ensure the consistency of bending work pieces.

- Low cost of use

Workers spend a lot of money on wages, insurance, accidents, etc. Hidden costs such as waste and scrap.

Robot bending is like a bending machine, which is a one-time investment, with low follow-up maintenance cost and low use cost.

- Enhance the image

Robot bending operation represents the highest level of bending automation, embodies the advanced processing capabilities and scientific research capabilities of the enterprise, and raises the corporate image and competitiveness to a higher level.

In the era of product upgrading, it is only necessary to design the corresponding tooling and fixture according to the new product, and the robot body does not need to be changed, and the corresponding program command is changed and the product can be updated.

2. Robotic plate bending applications

Bending machines have a wide range of applications and many types like robotic plate bending applications automotive. Most products can be bent by robots, but robot bending has long teaching time, and different work pieces require different fixtures. Comprehensive consideration of applicability and competitiveness. On the one hand, only certain areas are currently suitable for robotic bending.

- Large-scale sheet processing field with a lot of labor

- Standard electric cabinets, elevator door panels, anti-theft doors etc.

- Single piece large batch bending

- The overall speed is fast, the consistency of the work piece is good, the mood is stable, hard work

- Repeated bending in multiple batches

- After the program is written, the program can be called directly for the second use

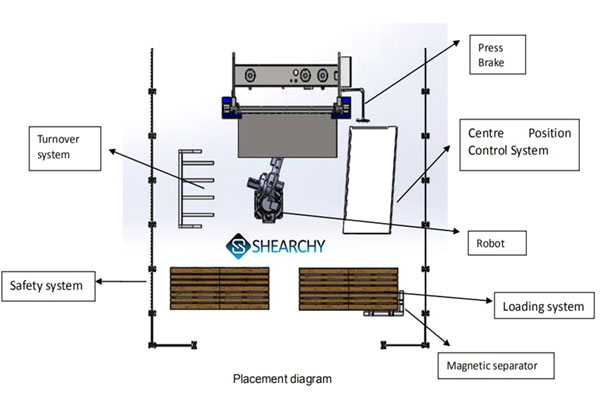

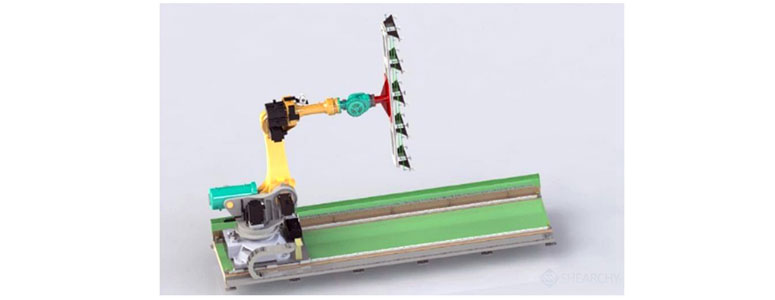

3. Configuration of robotic plate bending

- Loading system: including splitting device, sheet detection, etc., designed according to the quantity, size, and principle of easy grasping

- Common magnetic divider: Use super-strong magnetic field to magnetize the steel plate to be divided with the same pole, so that the mutual repulsive force between the multi – layer steel plates can be realized.

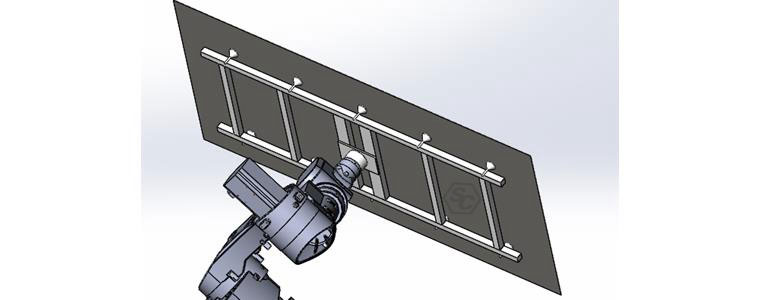

- Gripper system: generally include brackets, suction cups, vacuum generators, sheet metal detection, etc. According to different sheets, you can choose mechanical grippers, sponge suction cups, etc.

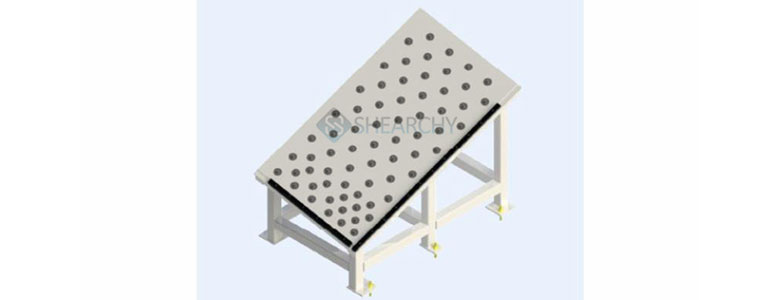

- Centre position control system: secondary positioning, search for “zero point”, precise calibration of the position of the sheet metal, mechanical or visual alignment, individually designed according to the size of the raw material.

- Back gauge automatic alignment system: including sensors, modules, communication modules, etc., fully closed loop automatic sheet alignment

- Safety protection system: including safety fence, safety light curtain, etc. Security fence and door lock. Generally the height is above 2000mm.

- Optional configuration

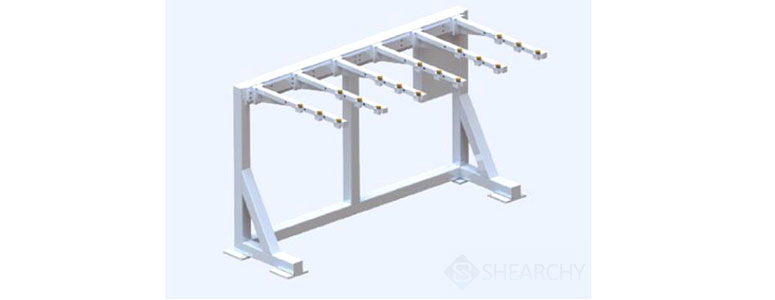

Turnover system: including bracket, suction cup, vacuum generator, etc

- The seventh axis of the robot: multiple bending machines or bending at different positions of the mold

- Automatic die change system: automatically update the bending die

- Automatic gripper change system: Automatically change grippers according to different bending sheets

4. Selection of robotic plate bending

- Requirements for press brake

In theory, electro – hydraulic machines can be used. Whether it is equipped with DELEM, ESA or CYBELEC system. However, the more the number of shafts in the back gauge, the more appropriate it is. If the back gauge is too simple, manual adjustment may be required when bending complex work pieces. Generally, electro – hydraulic bending machines with more than 6 axes are recommended.

- Influencing factors of robot bending selection

-

- Work piece size

- Work piece weight

- Bending process

- Other (automatic production line)

With the continuous development of the sheet metal manufacturing industry, robot bending has more and more broad application prospects. Compared with the development of special bending robots, the robot bending following model algorithm suitable for general six-axis robots is developed and applied to general robots. , The development cost is lower, and the robots of most excellent brands in the industry can be used with other auxiliary hardware to quickly promote the application of automatic bending machines. If you need to consult the robot bending, please contact us!