Description

Quick Details

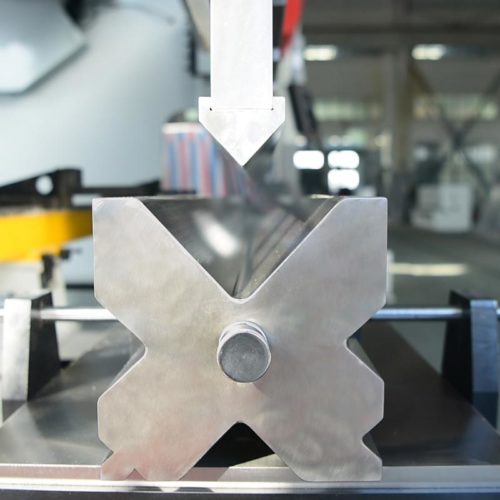

- Condition: New Brand Name: Shearchy Machine Type: Press Brake

- Raw Material:Steel plate Power: Hydraulic Certification: ISO, SGS, CE

- After-sales Service Provided:Engineers available to service machinery overseas

EASYBEND PRESS BRAKE Product Description

Throat deformation compensation mechanism to ensure the bending depth and precision

Forcing-torsion shaft maintains the synchronization of both cylinders with high precision

The stroke of RAM and back gauge could by adjusted through motor

Could be adjusted by hand wheel for fine position

The value adjusted could be displayed on numerator