The CNC sheet metal bender is a machine often used in place of a vertical press brake. The machine is capable of bending sheet metal work of many sizes, from a couple mm across to sections of sheet metal that are several meters long—for the largest industrial machines. Some machines have a fixed bottom bed and a V block tooling fixed in place and a top beam that uses force to travel under the V blade tools. That is the process of forming.

Other machines are up forming. The bottom bend moves and the top beam is stationary. Either method will produce sheet metal components that are the same and the best aspect of these machines is that the design of your components is not limited.

What is the function of a CNC sheet metal bender?

Metal bending is the process of re-shaping metals using brake press machines and other press machine types. CNC (computerized numerical control) presses are versatile and precise machines that can be automated for shorter completion times and heightened efficiency. The precision of the machine is enhanced by the computer programs that control the operation of the machines.

CNC metal bending is the programming of the press brake to form the sheet metal at the exact point the user needs the need to occur. This progress boils down to clams on the press brake holding the sheet metal in place.

Which industries commonly use CNC sheet metal benders?

Many industries take advantage of sheet metal bending machines and the components they produce. Nearly any industry you can think of uses these machines. Aerospace, automotive, construction, consumer products, furniture, agriculture, medical, military and defense, electrical, and many more.

The process of metal bending is a uniquely precise and efficient method that major industries use and benefit from.

1. Aerospace

Precise, well-produced and created metal materials are a must for the aerospace industry. Aircraft are expensive machines that require as much of a guarantee to safety and performance as possible. Aircraft endure intense strains and the parts that make up these huge flying machines must be shielded from corrosion, wear, and other intense forces.

CNC sheet metal bending can be used to manufacture components of the interior, and exterior and interior motion control and sensors and actuation systems. Metal bending machines are also capable of producing braking and landing parts and other parts that are critical to the safety of flight.

2. Automotive

A variety of metal materials are produced with sheet metal bending for the automotive industry ranging from cold roll steel, stainless steel, aluminum, and carbon steel components and parts. Some of those parts would be transmission covers, seat parts, brake components, battery housings, and many other parts used in building automotive engines.

Sound system components such as speakers and subwoofer chassis can also be crafted using metal bending. The applications of metal bending go beyond the mass industrial complex as well and extend to collectors and enthusiasts, who may buy bent aftermarket parts to upgrade sound or lighting systems. Many restorers seek out bent parts to reinject the classic look and feel to their older model vehicles. The sporting complex also takes advantage of these machines in the manufacturing of roll cages for race cars.

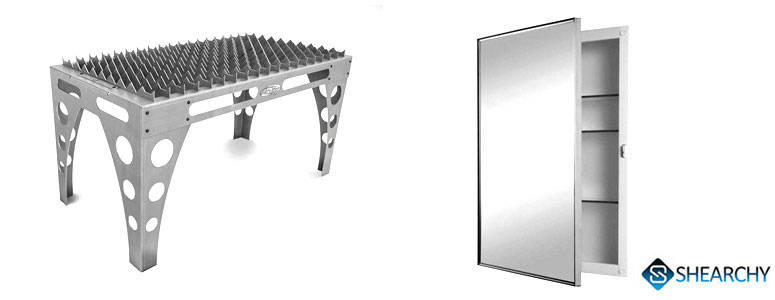

3. Furniture and Appliances

You’d be surprised how many consumer products take advantage of CNC sheet metal bending applications and methods. One of the major draws to metal bending is the machine’s ability to create aesthetically pleasing components that are perfectly rounded and finished. Parts that go into making stoves, microwaves, refrigerators, dishwashers, bed frames, entertainment centers, washing machines, dryers, cooling and heating units, and many more use components crafted from metal benders.

Outdoor furniture such as swing sets for kids, patio tables and chairs, trampolines, and others are crafted with the use of sheet metal bending machines.

There are many different types of machines for CNC sheet metal bending. For instance, a Form Bender is a great tool for hobbyists, iron artists, and anyone who works with smaller materials that need bending. Slip Roll benders allow the operator to create patch panels for lower fender areas, roll pans, rockers, and door skins. Folding Machines can handle large sheets and are easily automated.

Summary

The overall usage of CNC sheet metal bending machines is extensive. Many industries make use the machines for many different applications and purposes. That fact alone speaks to the wide range of uses these machines have. Constant innovation has pushed the machines forward and allowed their uses to expand across multiple avenues where there wasn’t a demand previously.

Medical fields are assisted by CNC sheet metal bender in the manufacturing and production of high-tech and crucial equipment such as x-ray machines, components to emergency vehicles, and the actual construction of hospitals and doctor’s office buildings.

The usage and importance of metal bending machines cannot be understated. Without these machines, precise crafting would not be as widely possible and instituted as it is today. The industrial world has always been at the forefront of innovative design to further outside industries, and that remains true to this day.

Military and defense industries employ sheet metal metal benders to design and craft components to weapons, vehicles, and equipment. The military complex is one of the most invested in complexes the world over, and the usage of advanced machinery such as metal benders speeds up the processes of building and testing new equipment.