What is sheet metal roller lubricating oil?

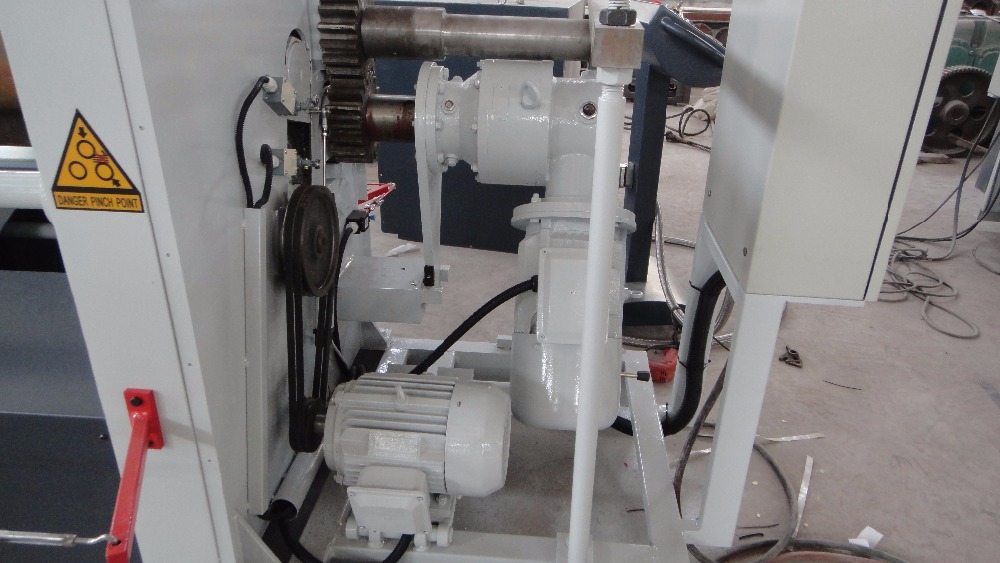

Metal roller lubricating oil is a kind of liquid or semi-solid lubricant used to reduce the friction of rolling machine. So it can protect machines and processing parts. It mainly plays the role of lubrication, auxiliary cooling, rust prevention, cleaning, sealing and buffering. Shearchy Plate Bending Rolls are all equipped with hydraulic oil of suitable viscosity and good temperature resistance.

What performance requirements should the oil of the plate rolling machine meet?

Suitable Viscosity & Good Temperature Resistance

-

The viscosity of lubricating oil is related to the starting property of engine, wear degree of engine parts, consumption of oil and power loss.

The viscosity of the oil is too large and poor fluidity, it takes a long time to enter the friction surface. Also, cleaning and cooling performance is poor. As a result, fuel consumption and parts wear will increase. However, such oil seals better. Too small viscosity of oil cannot form a reliable oil film and maintain lubrication. Therefore, the poor sealing of such oil will result in much wear tear and power reduction of the rolling machine. In conclusion, the viscosity is too big or too small is not good, it should be appropriate.

-

Pay attention to clean the lubrication system to maintain good performance of hydraulic system

When the sludge and other dirt produced by the lubrication system are too much, the dirt will be separated from the oil. This causes oil filter and oil hole blockage, poor oil mobility, piston ring adhesion, increased fuel consumption, power reduction and other phenomena. In order to prevent the above faults, it is necessary to add a solvent dispersant in lubricating oil. The dispersants are mainly divided into metal dispersants and ash – free dispersants.

-

Excellent Lubricity

Most engines use sliding bearings and bear heavy loads. Engine lubricants must have good lubricity under high load and high pressure.

-

Good Ability to Neutralize Acid

Good fuel, especially diesel, contains a lot of sulfur. The acid gas produced after combustion combines with water to form sulfuric acid or sulfite solution. These acids will corrode the metal in the engine. Therefore, lubricating oil is required to have a good ability of neutralization with acid, so as to reduce the damage of acidic substances produced by combustion to the engine.

-

Good Oxidation Resistance and Thermal Oxidation Performance

Lubricating oil will combine with oxygen at high temperature. Then, its oxidation products will make the lubricating oil deteriorate and fail. When metal roller machine manufacturers check and repair equipment for customers, they find that it is one of the main causes of many engine failures. Machine oil should add in various antioxidant additives to avoid oxidation deterioration.

-

Good foam resistance

Because of the crankshaft strong agitation and splash lubrication, it is easy to make oil bubbles. Consequently, its lubrication performance will decline and lead to the failure of the oil pump. Moreover, good foam inhibitor products must be added to the lubricating oil to inhibit the production of foam and maintain the efficacy of lubricating oil.

Wuxi Shearchy is a professional metal forming equipment supplier in China. Welcome to visit our website for more details about bending machine, shearing machine and rolling machine. We look forward to cooperating with you!