CNC Brake Press is one of metal forming products of Shearchy Technology. Moreover, it is also has different model sizes and common classifications. Below, we will analyze through some specific questions.

What is the difference between hydraulic press brakes and hydraulic pipe bending machines?

Hydraulic brake press VS pipe bending machine

The main difference between these two metal forming machineries:

The main difference is in the usage and applications.

- CNC Hydraulic press bender is a device for bending a thin metal plate.

- Pipe benders is for processing the pipe.

- Therefore, they cannot be replaced by each other.

How to adjust the bending size in the CNC brake press?

For the bending size adjustment, it is not difficult for professional press brake factory.

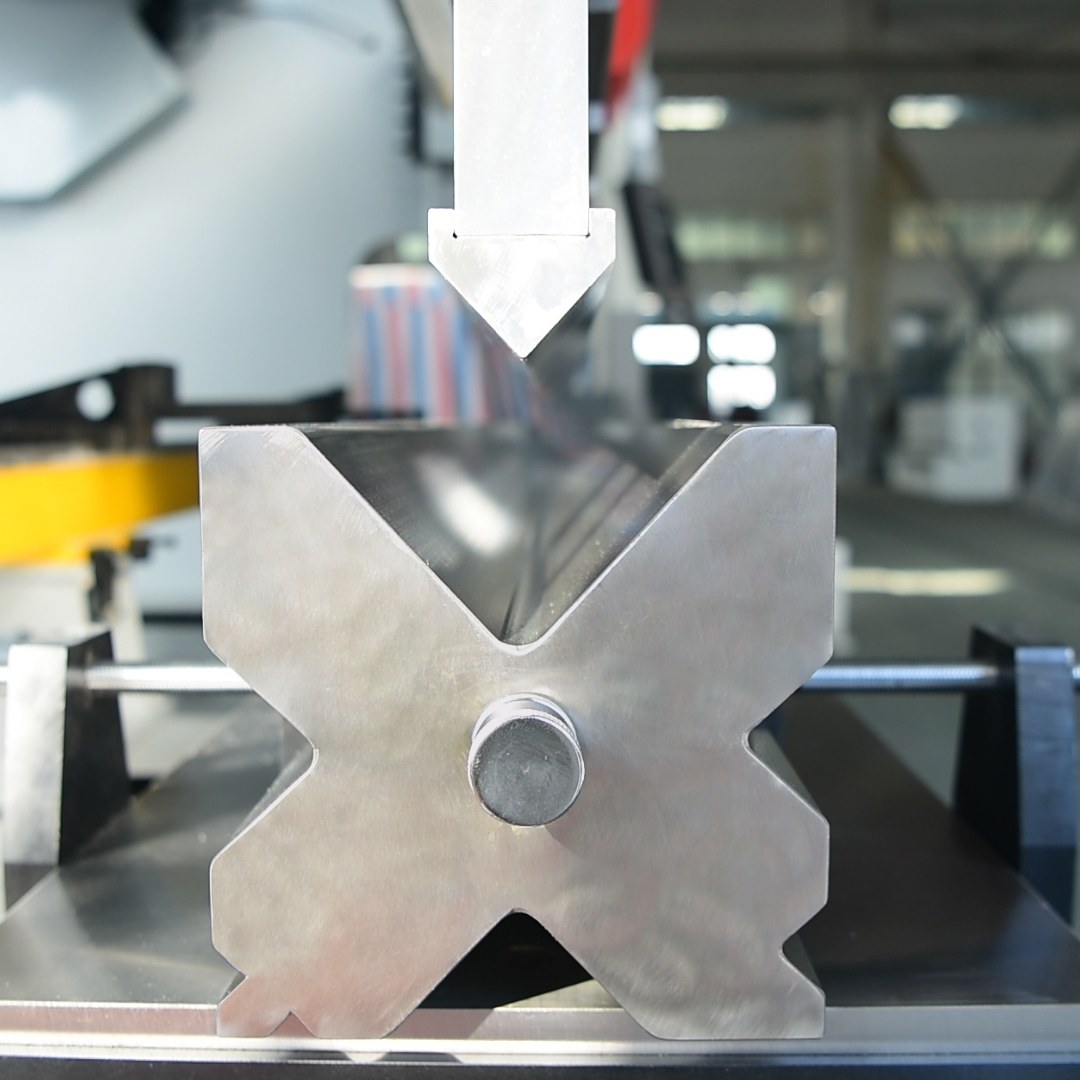

Specifically, we can make rough adjustments and fine adjustments by pressing the button on the lower right side of the machinery. That is, adjusting the size of the back gauge. For the bending angle, we should change the press brake punch and die, such as depth of mold V-groove. In general, we can carry out and implement through the wheel.

Machinery knowledge that users must master

Necessary knowledge of CNC brake press operation

Before metal bending operation, the user should make a reasonable choice and correct determination of the bending force and the opening size of lower mold V-groove. Generally speaking, it is possible to depend on the thickness and length of metal plate.

More detailed information about press brake tonnage calculation, you can click here:

How to calculate Press Brake Tonnage?

It is necessary to adjust the gap through the center of the upper and lower die and determine the position of the front and back gauge, as well as the specific process flow. So, it will get a good bending effect.

For all sealing elements in the metal benders, please conduct a thorough inspection. The sealing performance is closely related to the machining accuracy and durability. Therefore, it is necessary to periodically check whether need change.

We have 10 years exporting experience and have already exported machines to more than 35 countries all over the world. Welcome to contact us with your requirements!